-

brands

- Anep

- Avire

- Bernstein

- Blain

-

Bucher

- Cedes

- Dictator

- Divers, Universal

- DMG

- Falconi

- Fermator

- Fiam

- Forsid

- GAL

- Gervall . Aljo

- GMV

- Haushahn

- Hydronic

- IGV

- Kone

- Kronenberg

- Kuhse

- MAN

- Meiller

- Microlift

- Monitor

- Orona

- Osma

- Otis

- P+S

- Perjes

- PFB

- Prisma

- Prudhomme

- Riedl

- Safe Line

- Schaefer

- Schindler

- Schmersal

- Schmitt & Sohn

- Selcom

- Semag LifterCo

- Sematic

- SKG

- TK Elevator/Thyssen

- Vega

- Wittur

- categories

- products

- types

- dimension wizard

- top article

- new

- outlet%

- blog

- career

Spare parts for Bucher hydraulic elevators? Hauer’s got it!

When the conversation drifts to hydraulics in the exciting and creative elevator and escalator sector, Bucher is the name that always immediately springs to mind. Headquartered in Klettgau, near Waldshut in southern Germany, Bucher has earned its outstanding reputation as a reliable and highly competent supplier to companies all over the world by meeting and exceeding the highest demands in a wide range of designs. The company has consolidated its prominent position in the elevator industry, particularly in the development and production of bespoke system solutions in both mobile and industrial hydraulics.

Perfect hydraulics are essential fundamental elements of elevators, which is why being able to rely on your partner – and, in turn, on the units and replacement parts they deliver – is of prime importance. Bucher remains a family business to this day and offers a wide range of products encompassing not only pumps, motors, cylinders and valves, but also highly sophisticated drive units and top-quality elevator drives, as well as state of the art control systems and circuit boards, all of which never fail to impress.

Where customer service and bespoke solutions are concerned, the Klettgau company never loses sight of what its partners value the most. Their local mentality hasn’t stopped the leading manufacturer of hydraulic components being recognised as a genuine global player in the sector, though. Indeed, Bucher Hydraulics has a number of locations outside of Europe – both in Asia and the Americas. This ensures that the worldwide leader of cutting-edge hydraulic system solutions can maintain a presence in all markets, thus affording them that ever-important proximity to their customers.

Expertise, technical knowledge and competence… staying one step ahead

With around 2,000 employees working across several different sites, the company truly has an enormous pool of skill and technical expertise to dip into. This is complemented well by an experienced sales team that provides Bucher’s customers with comprehensive support throughout the decision-making process – and they do so with an astonishing level of competence. When in-depth technical expertise and knowledge of their products is what’s needed, the application specialists and development engineers come into their own, especially when delivering complex solutions, adhering to the highest standards in all aspects of safety and security, and fulfilling bespoke system solutions punctually and properly.

Bucher continues to raise the bar where customer proximity and the consistent meeting of targets are concerned. Whether it’s technology, manufacturing quality or logistical flair in areas such as delivery and customer service, specialists at the company routinely develop highly effective individualised concepts that are beyond comparison.

With a constant eye on the changes and developments in the entire vertical mobility market, Bucher has been expanding its range over time… innovative new products are being added on a regular basis as, alongside pumps, motors, valves and cylinders, their comprehensive product portfolio now also features compact power units, elevator drives and control systems.

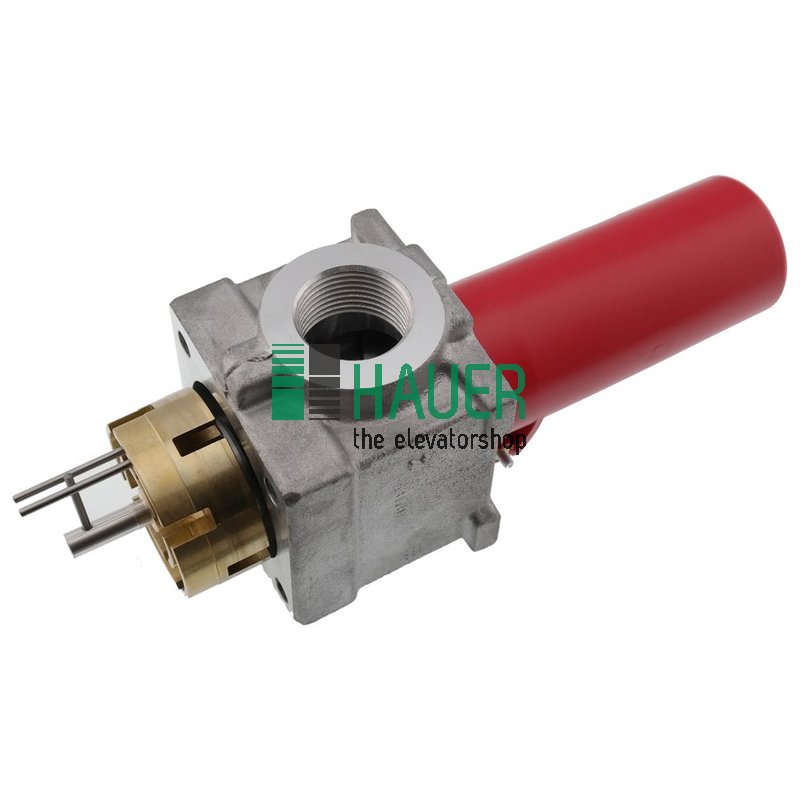

Perfect components for holistic solutions

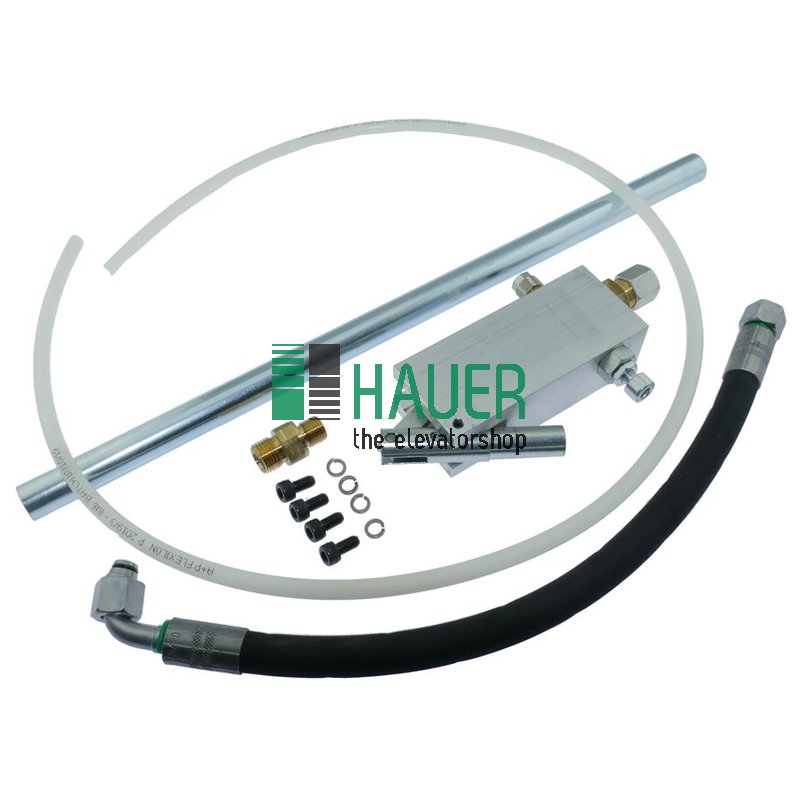

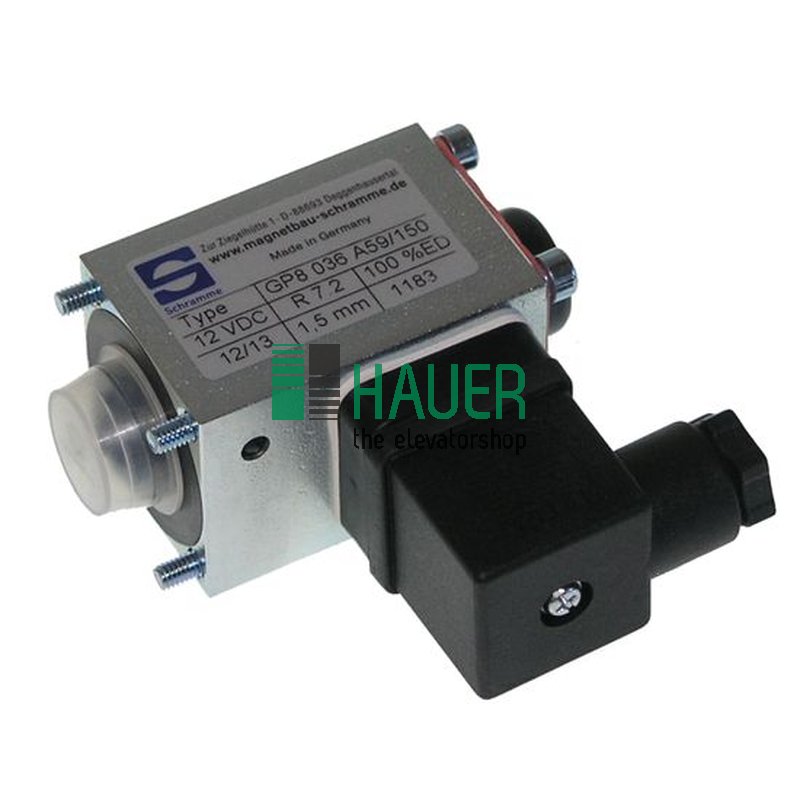

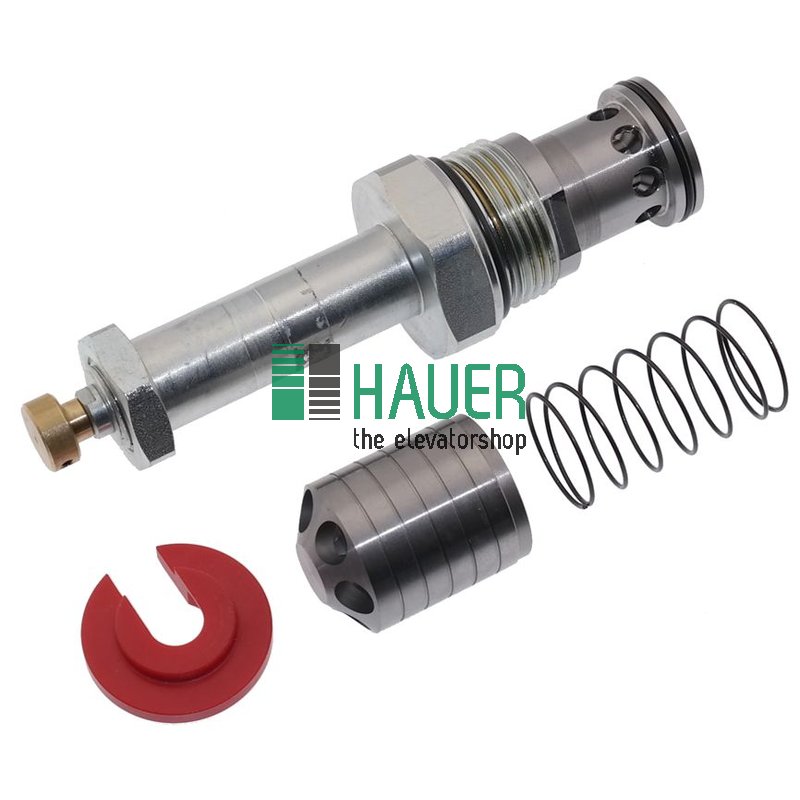

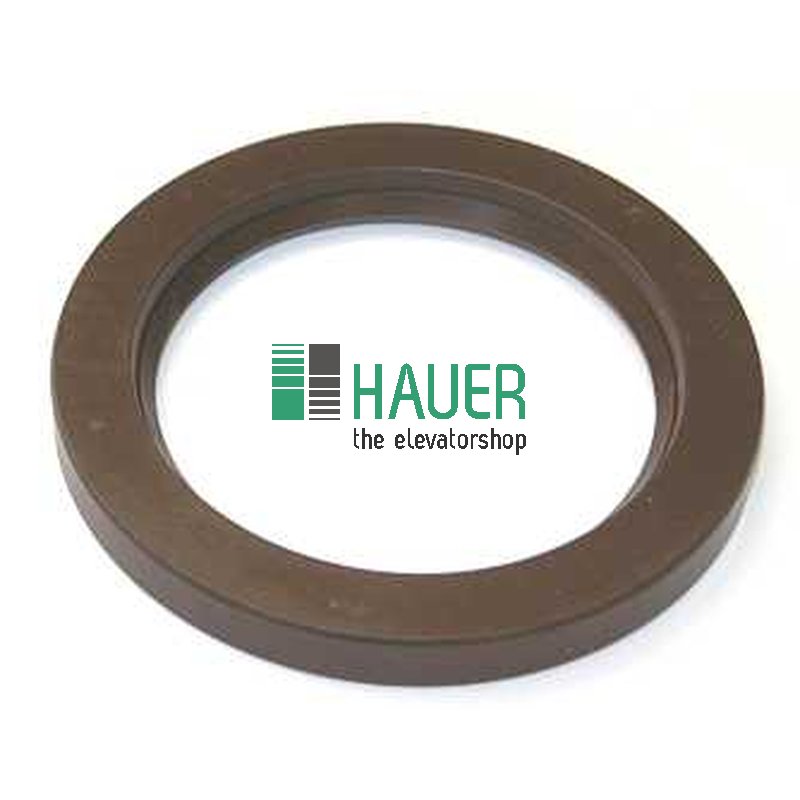

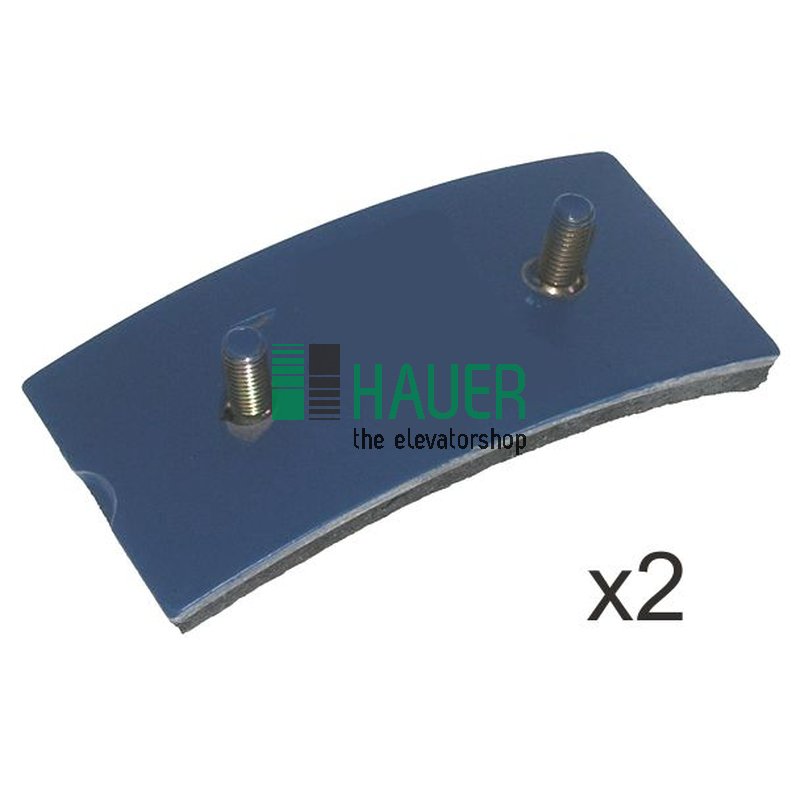

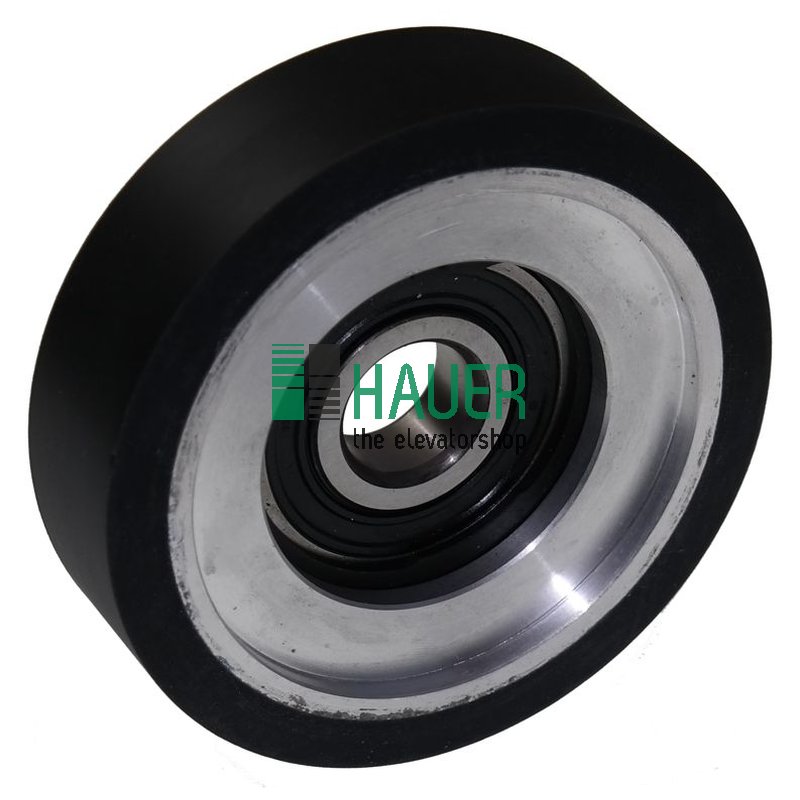

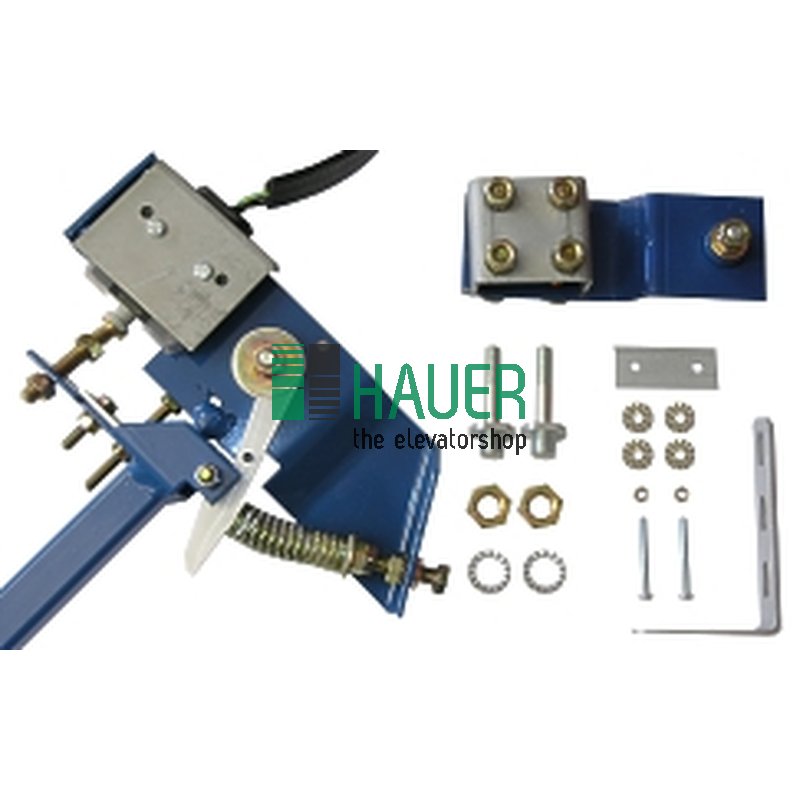

That Bucher’s extensive expertise and the high functional reliability of its hydraulic solutions have enabled them to become established on the market over the decades is the result of many factors, including the great importance they attach to the smaller, individual components they supply, such as seals, circuit boards or elevator control valves. The Baden-based company truly deserves its reputation as a leading international supplier of hydraulic drives and control technology in both mobile and stationary hydraulics.

Serving as an excellent demonstration of how concretely and consistently the company’s tinkerers focus on user requirements, the Bucher Hydraulics “iValve” is a prime example of the company’s innovative strengths. If all potential tasks and technical possibilities are thought through well enough, there’s no reason why the customers’ requirements in terms of individual components and systems can’t be fulfilled. Equally important is that any replacement parts required are delivered quickly – and they can be, from the Hauer elevatorshop.

The “iValve” was, in fact, developed in response to two trends that have become apparent in recent years. Firstly, it has become apparent that in-depth knowledge of the often complex issues surrounding hydraulics is becoming increasingly less available on construction sites. In addition, the demand for remote management has risen sharply – this is no surprise, given the age of globalisation we now live in.

This is why Bucher has streamlined its installation procedures, all the while continuing to develop new elevator units in all shapes and sizes, from small passenger lifts to large freight elevators. The “iValve” represents a revolutionary innovation, combining all the advantages of their tried and tested products with the latest trends and developments.

World class elevators from Bucher

Bucher’s innovative power units also ensure a high level of ride comfort, regardless of the load. For example, the hydraulic elevators in the “Comfort Line” can lift any total load to heights of up to 25 metres. The simple, compact design allows for optimised container sizes without compromising travel times. That neither oil cooling nor heating is necessary in most cases definitely constitutes a significant advantage, as energy costs are reduced.

The “Eco Line” is perfect for saving energy, guaranteeing maximum drive performance for both new installations and modernisations. The savings this frequency-controlled technology will help you make mean that it’ll pay for itself in no time.

Bucher’s “iPack” truly is a “unit with control”. This standard elevator, primarily used in apartments blocks, is A3 certified. The criteria for the final certification are even included! Perfectly practical, the “iPack and its control cabinet can be installed quickly and conveniently thanks in no small part to its pre-assembled cabling, self-adjusting valve and perfectly matched components.

User-friendly electronic controls, extremely flexible hydraulics and, increasingly, easy remote operation – it’s no wonder that Bucher Hydraulics continues to set new standards in the international elevator and escalator sector. Of course, commercial success is important to the company, but, in reducing their consumption of raw materials, fuel and water, they have also long since committed to employing environmentally responsible manufacturing methods, thereby consistently adhering to the strictest of standards. Efficient use of energy and environmentally conscious handling of hazardous substances also form an integral part of this, as do significant efforts to reducing emissions and waste. Indeed, working in this manner means that Bucher Hydraulics will implement all its environmental management system processes and services in the best possible way.

When it comes to hydraulics, which deals with the flow behaviour of fluids for signal, power and energy transmission, the primary considerations centre around physical characteristics. However, Bucher has consistently shown that their focus is on the wishes and requirements of their customers and that the market can rely on its outstanding engineering and development services. Nothing will change, here…