-

brands

- Anep

- Avire

- Bernstein

- Blain

- Bucher

- Cedes

- Dictator

- Divers, Universal

- DMG

- Falconi

- Fermator

- Fiam

- Forsid

- GAL

- Gervall . Aljo

- GMV

- Haushahn

- Hydronic

- IGV

- Kone

- Kronenberg

- Kuhse

- MAN

- Meiller

- Microlift

- Monitor

- Orona

- Osma

- Otis

- P+S

- Perjes

-

PFB

- Prisma

- Prudhomme

- Riedl

- Safe Line

- Schaefer

- Schindler

- Schmersal

- Schmitt & Sohn

- Selcom

- Semag LifterCo

- Sematic

- SKG

- TK Elevator/Thyssen

- Vega

- Wittur

- categories

- products

- types

- dimension wizard

- top article

- new

- outlet%

- blog

- career

Spare parts and components for PFB products? Hauer’s got ’em!

When PFB, a long-established manufacturer of lift components based in Modena in northern Italy, started looking for a distribution partner in Germany a few years ago, there was only one choice: Hauer. Now all customers looking for spare parts and components with that “Made in Italy” seal of approval can obtain everything they need easily, quickly and economically – from the Hauer elevatorshop.

“PFB SRL – Mechanical Lift Components”, to use its official title, entered the vertical mobility sector as early as 1970 and immediately set to work, quickly making a name for itself by producing first-rate lift components with the pride, passion and Italian flair you would expect.

In 1959, when Franco Bevini founded a small company bearing his initials in the northern Italian university town of Modena, mechanical engineering was the crux of his activities – he did dabble occasionally in the development of lifts, but his main focus was on general mechanics. His company’s first shift in emphasis came in 1964 with the arrival of two engineers named Pinzetta and Baraldi. Their aim was to consolidate Bevini’s success and to ensure that the company had a unique selling point like no other. Renamed PFB shortly thereafter, they gradually began to redirect focus towards mechanical precision machining.

Innovative components from Modena

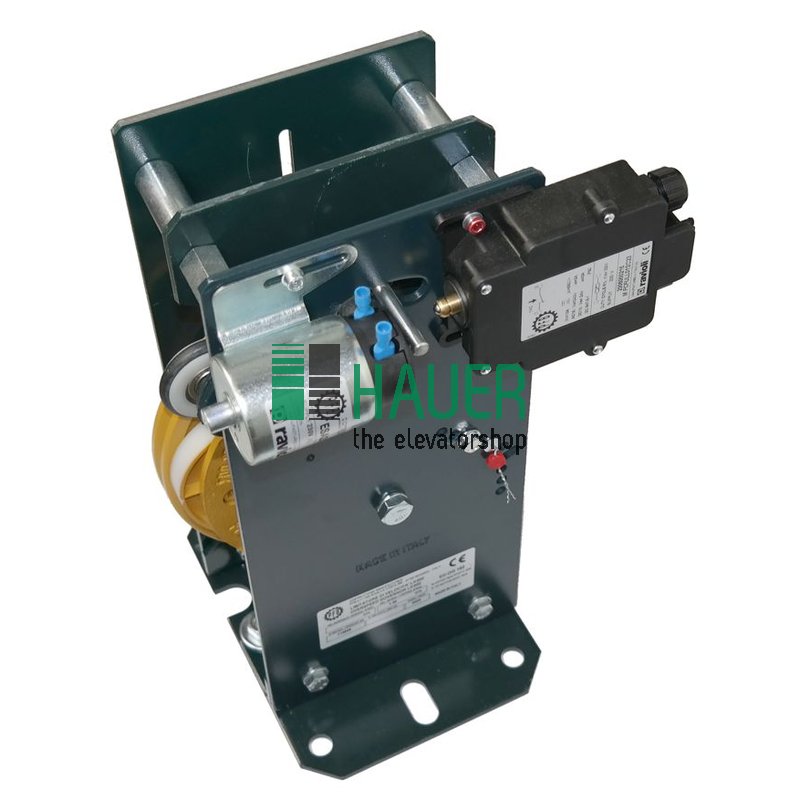

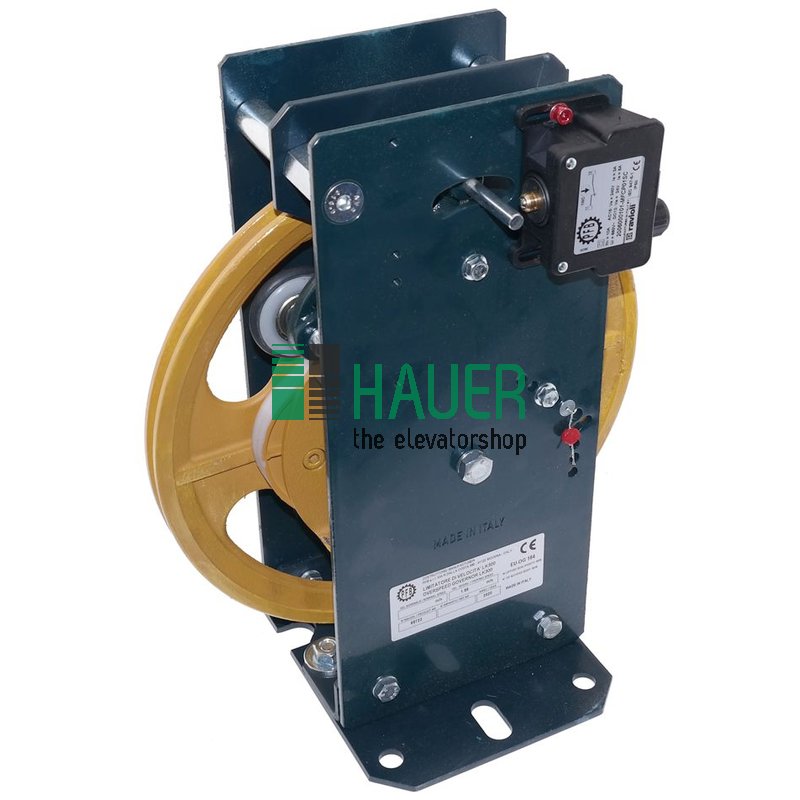

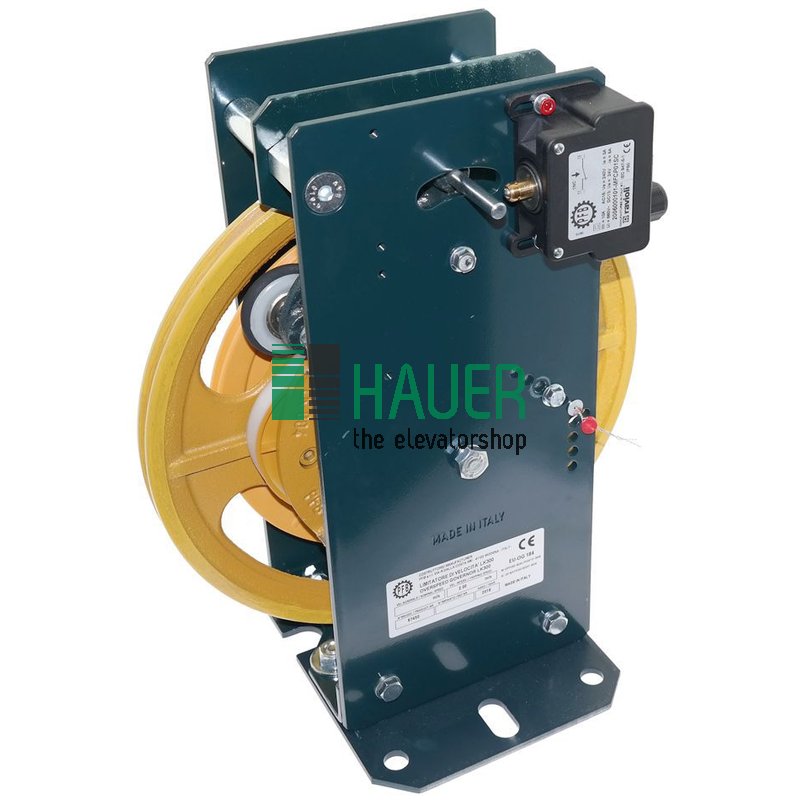

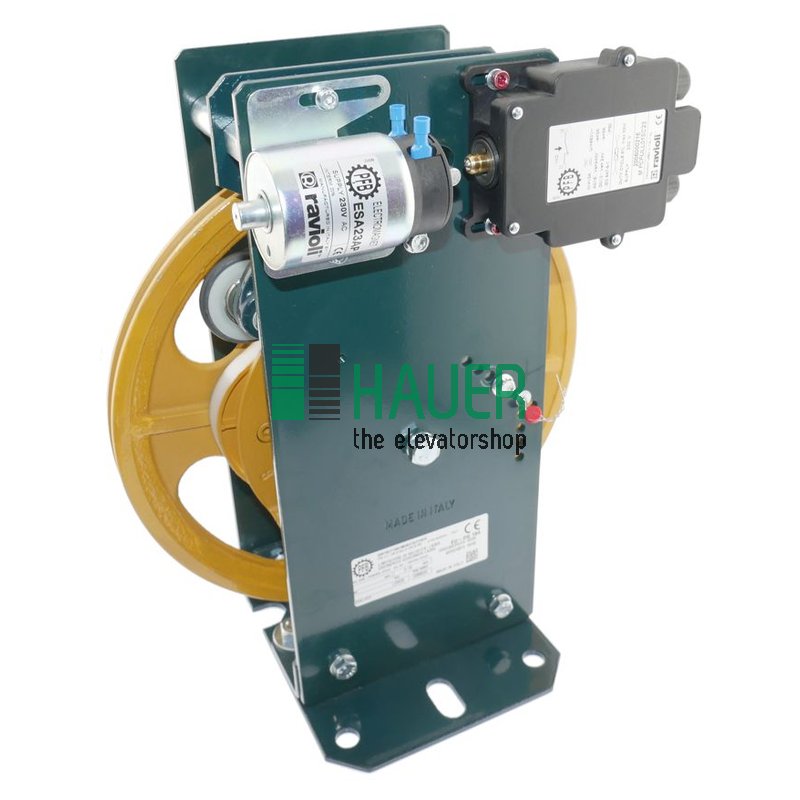

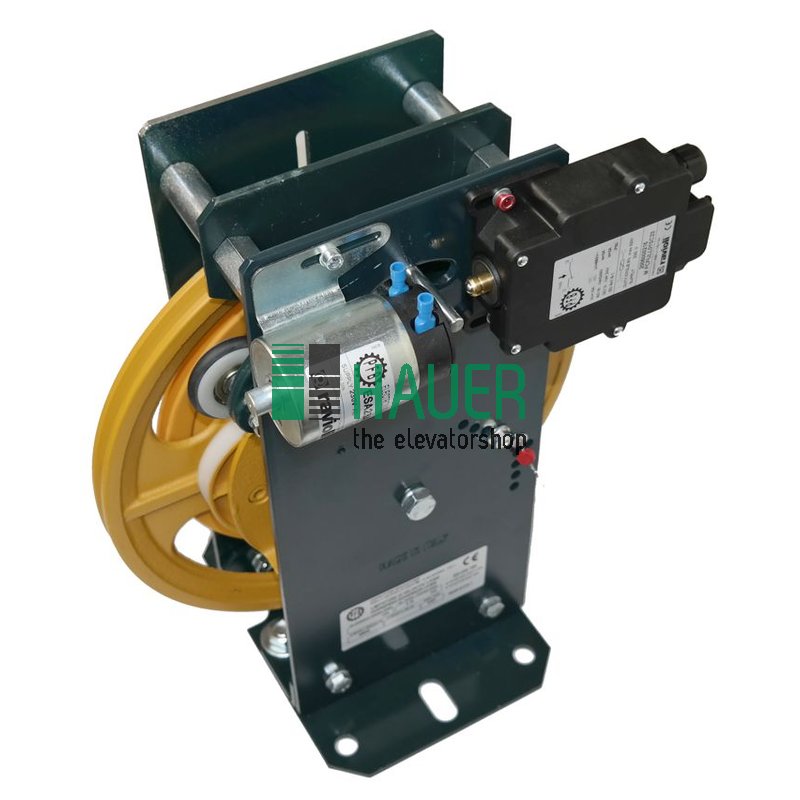

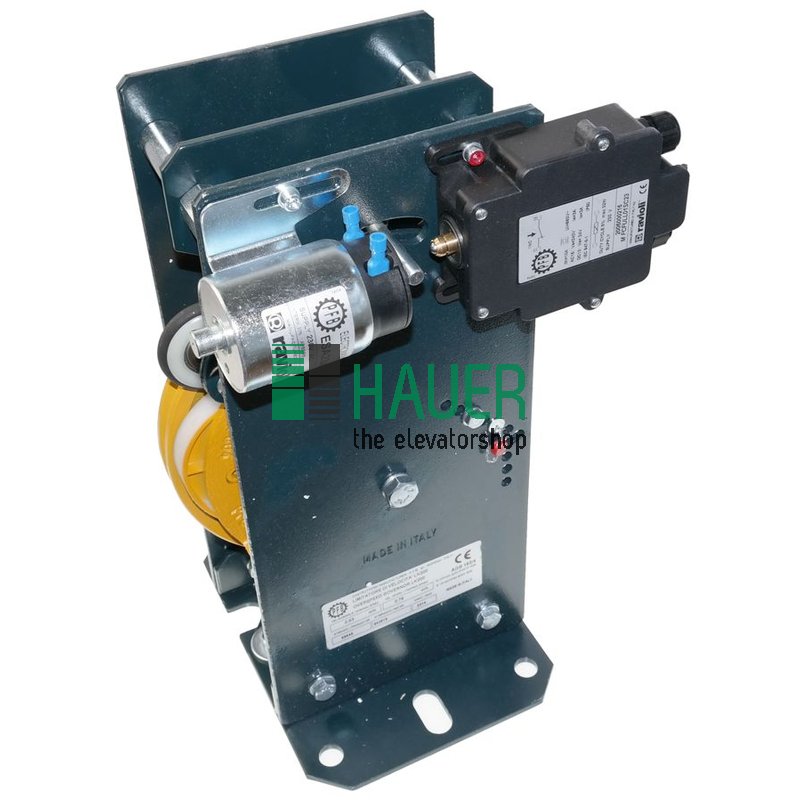

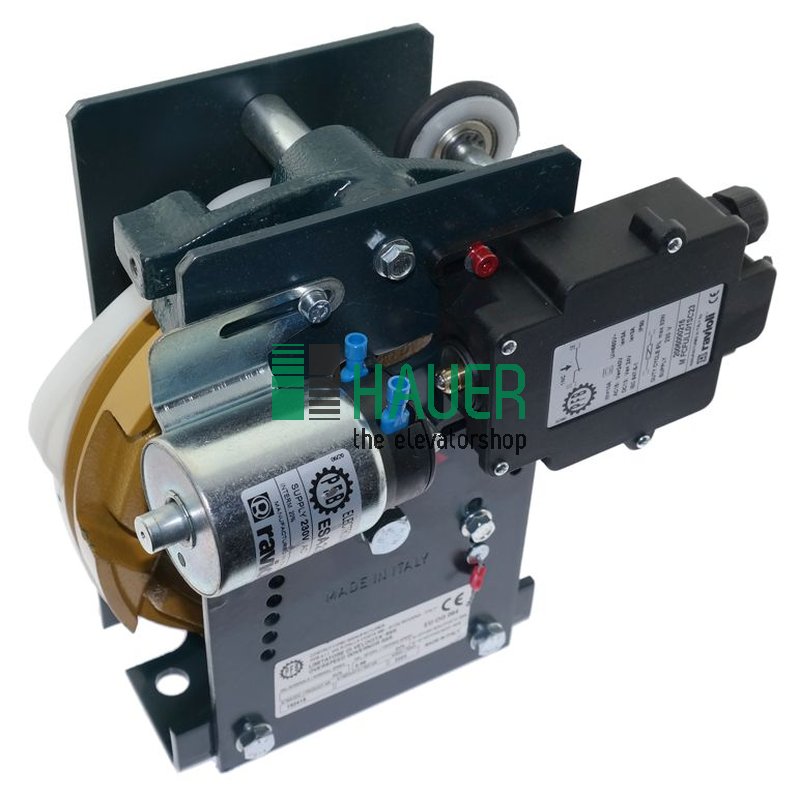

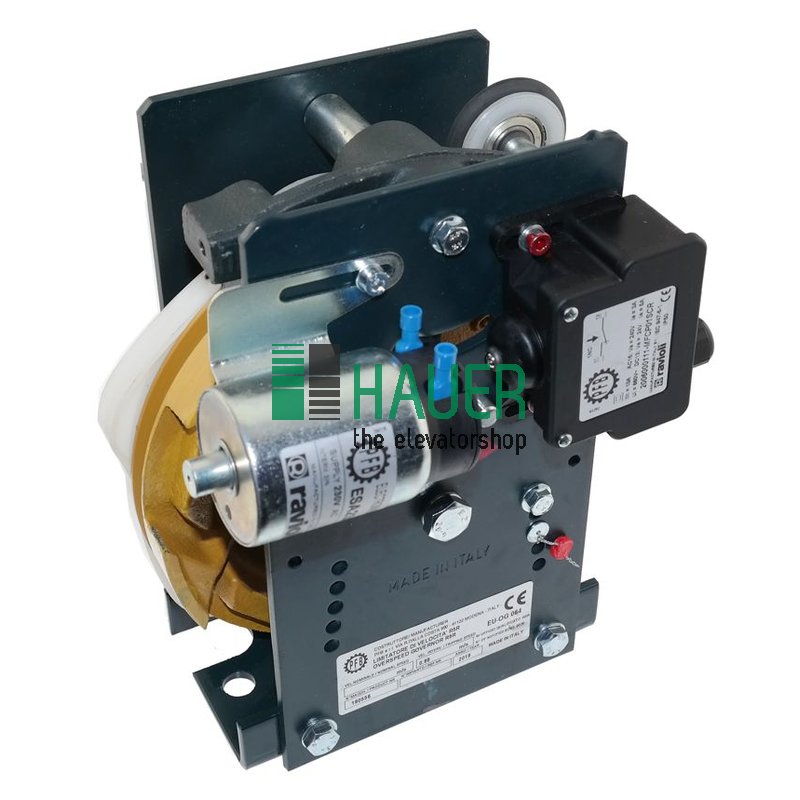

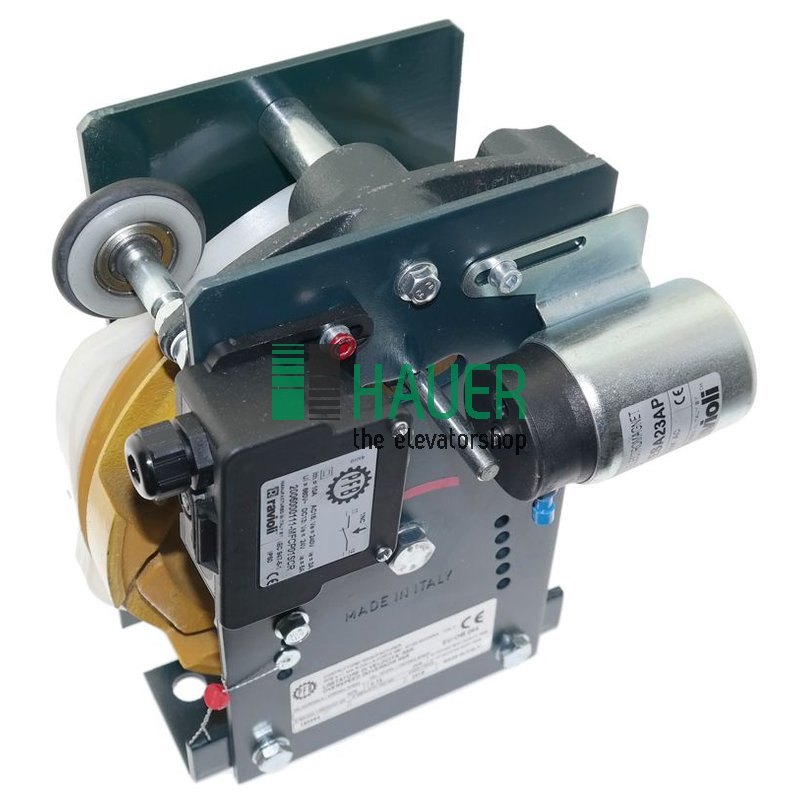

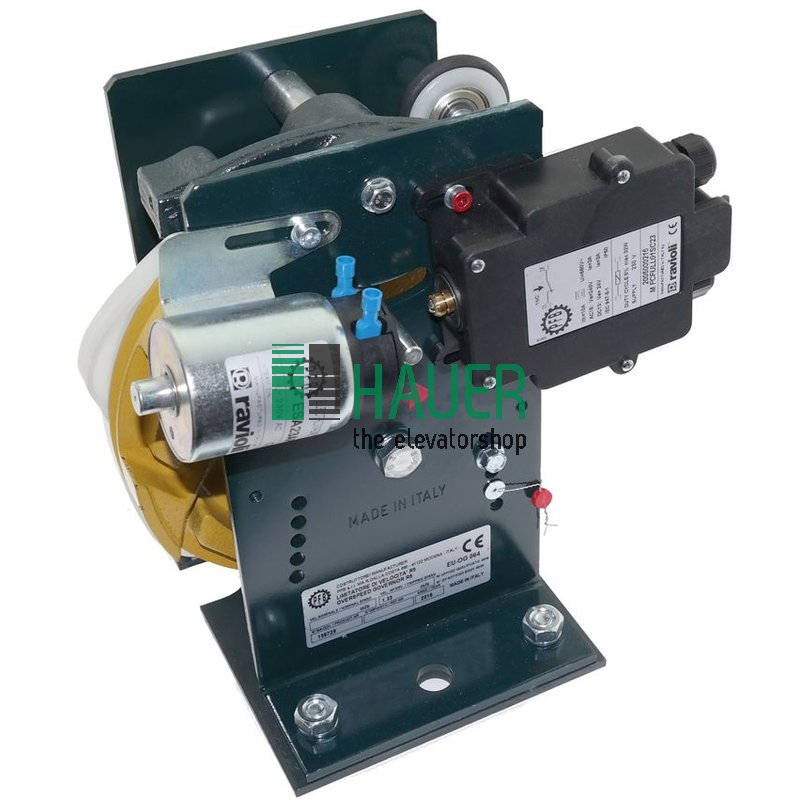

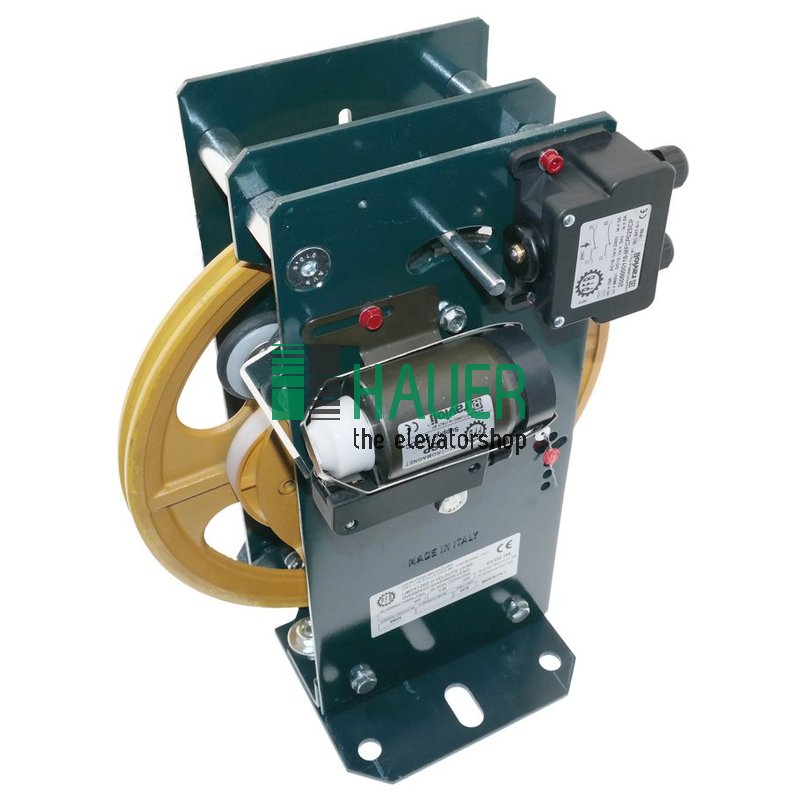

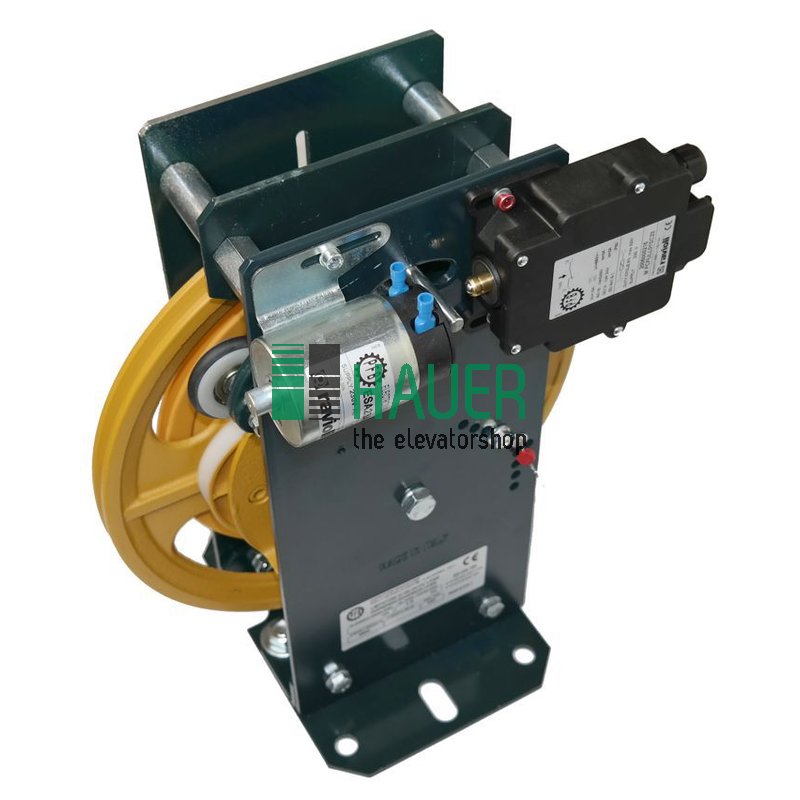

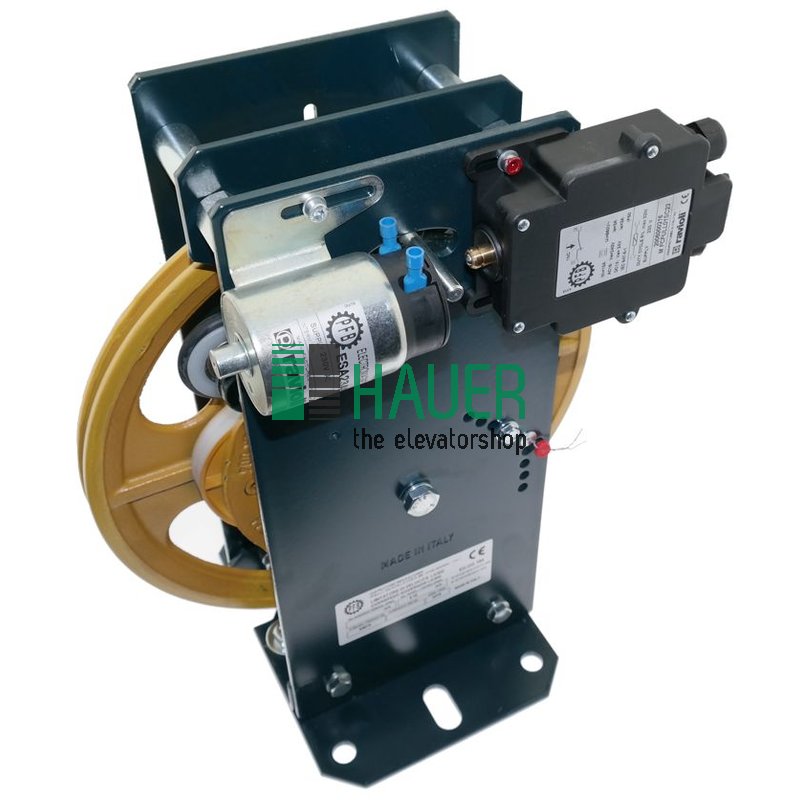

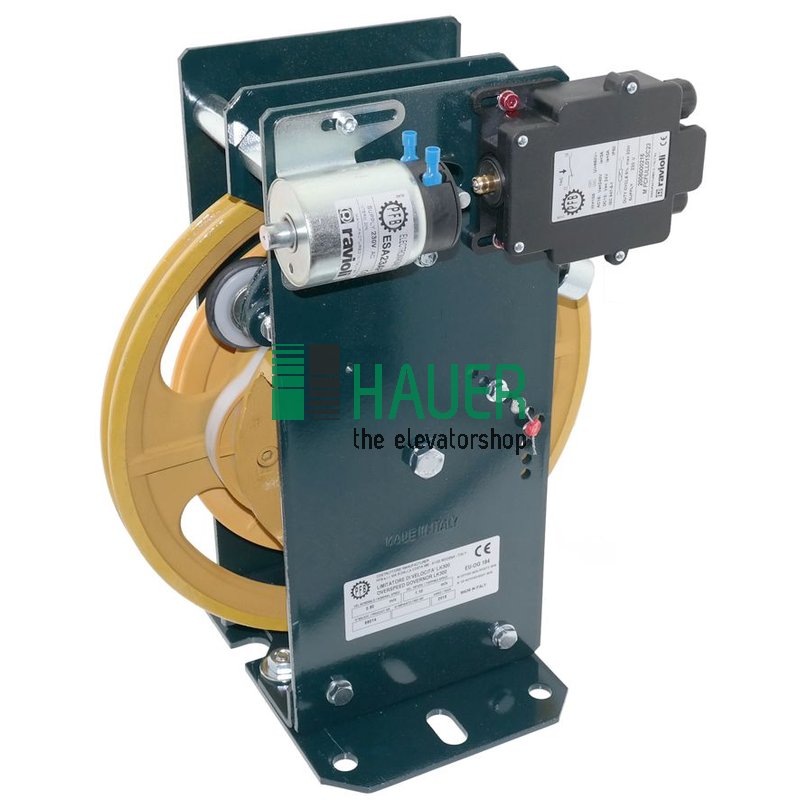

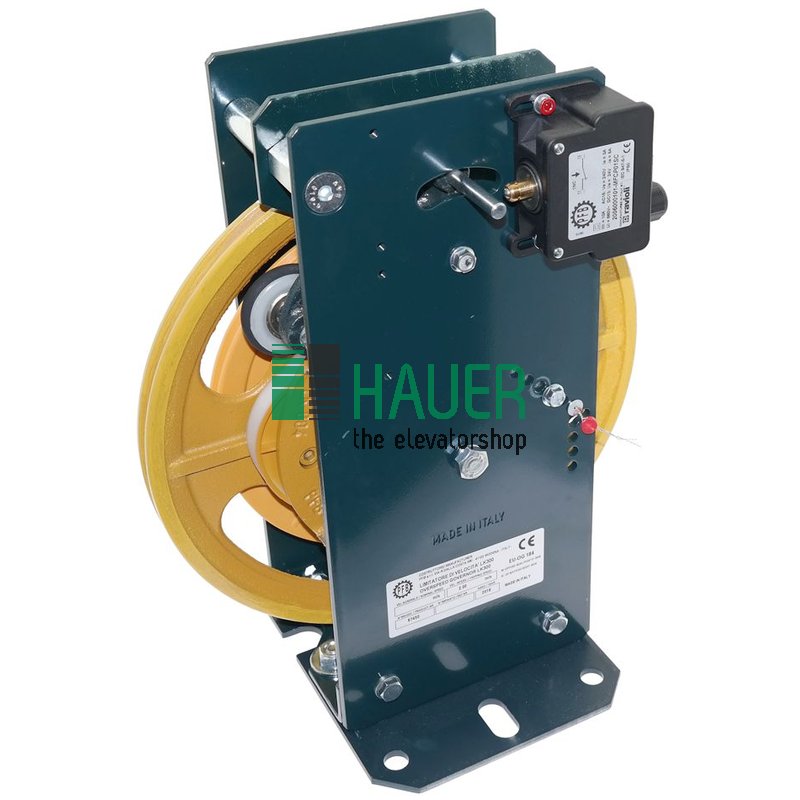

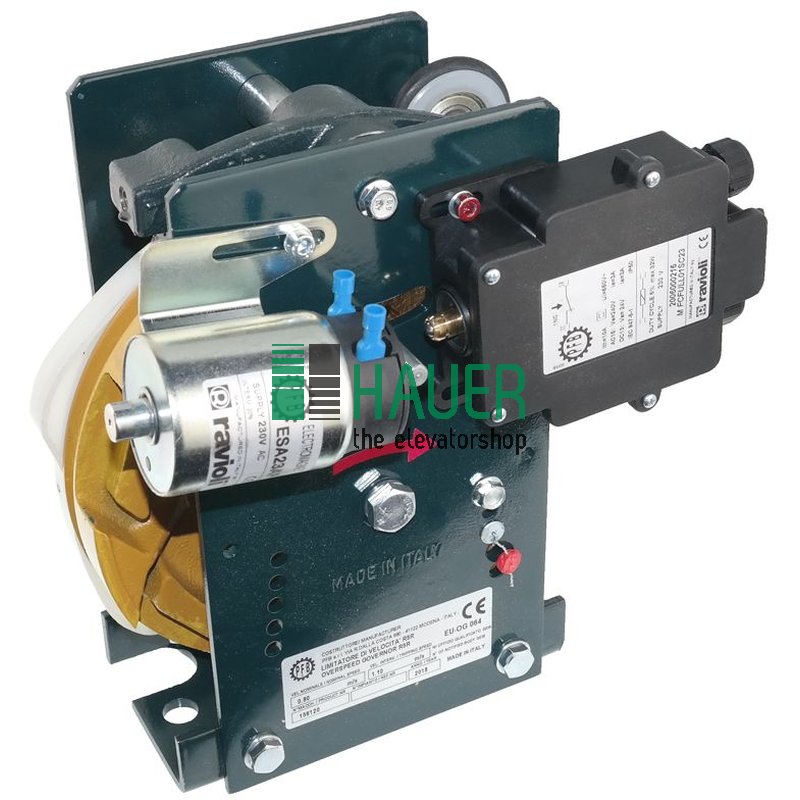

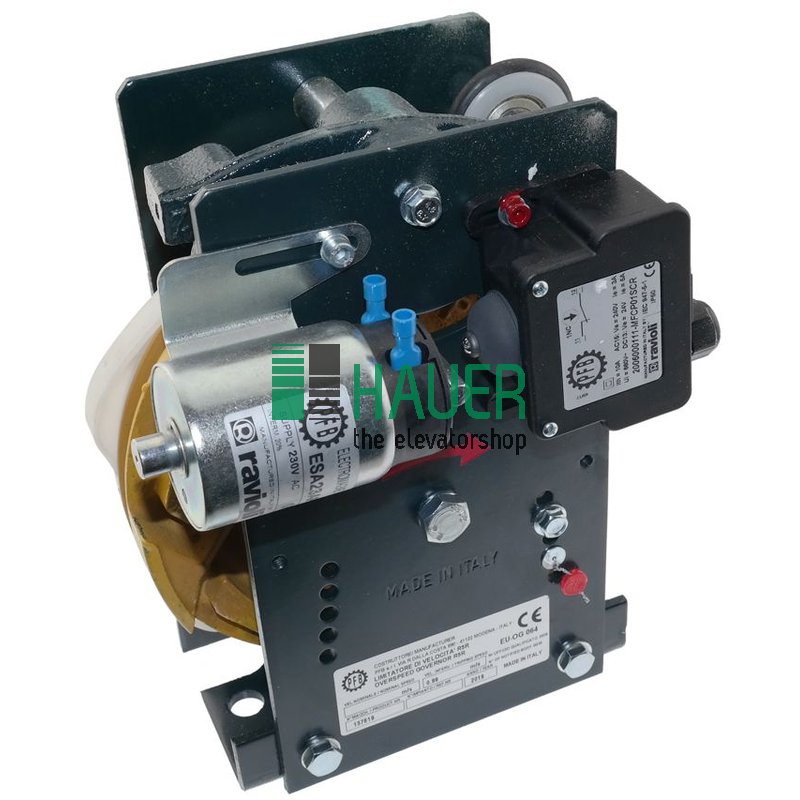

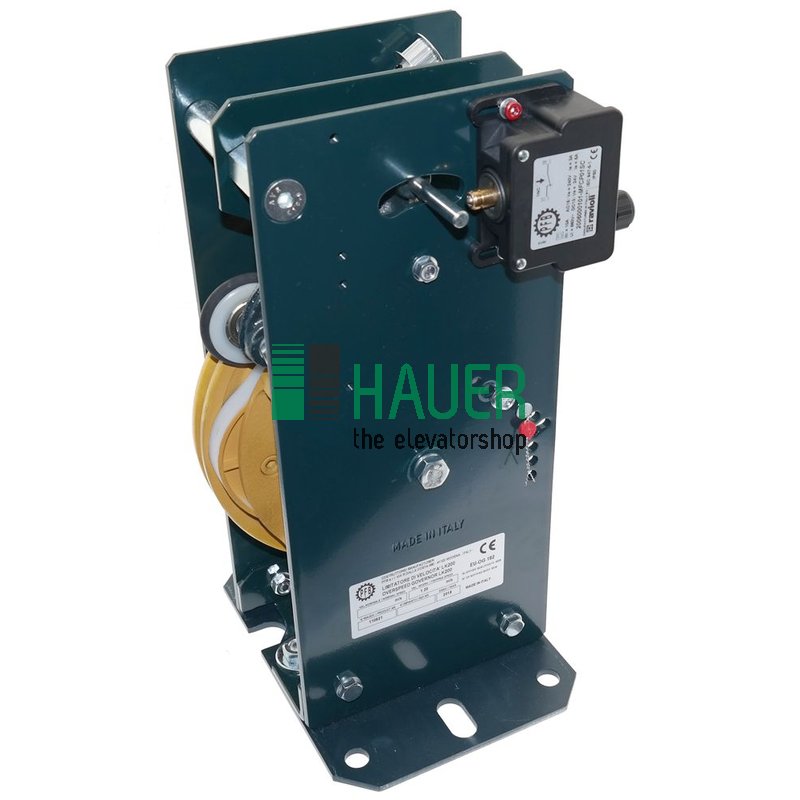

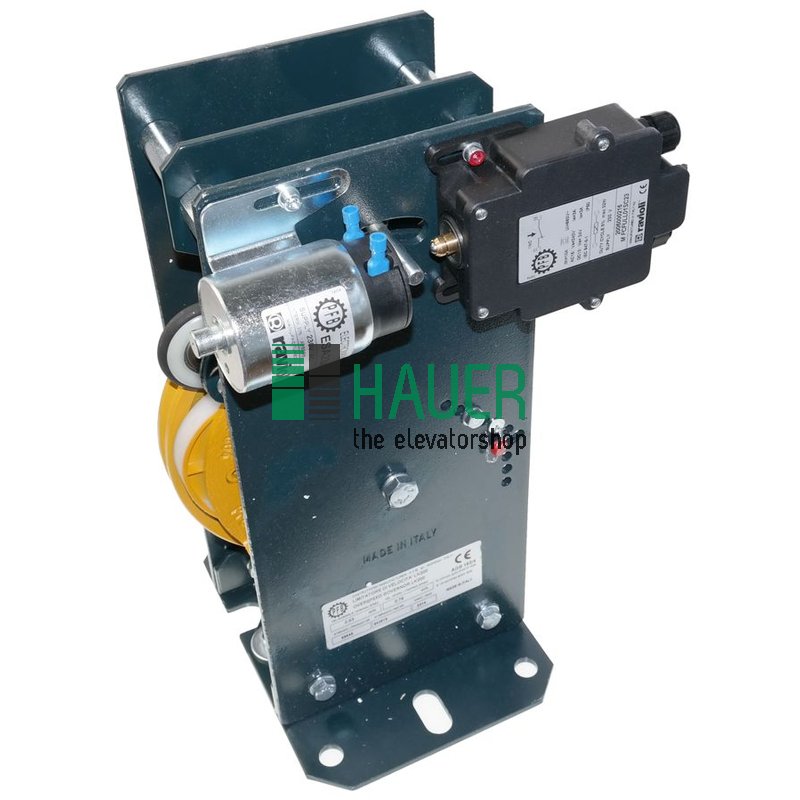

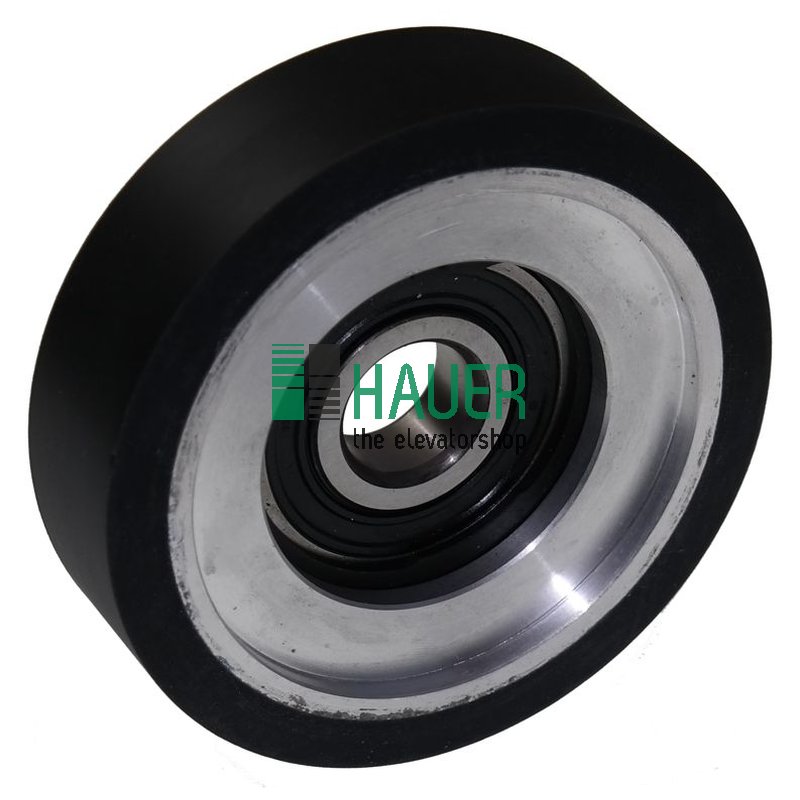

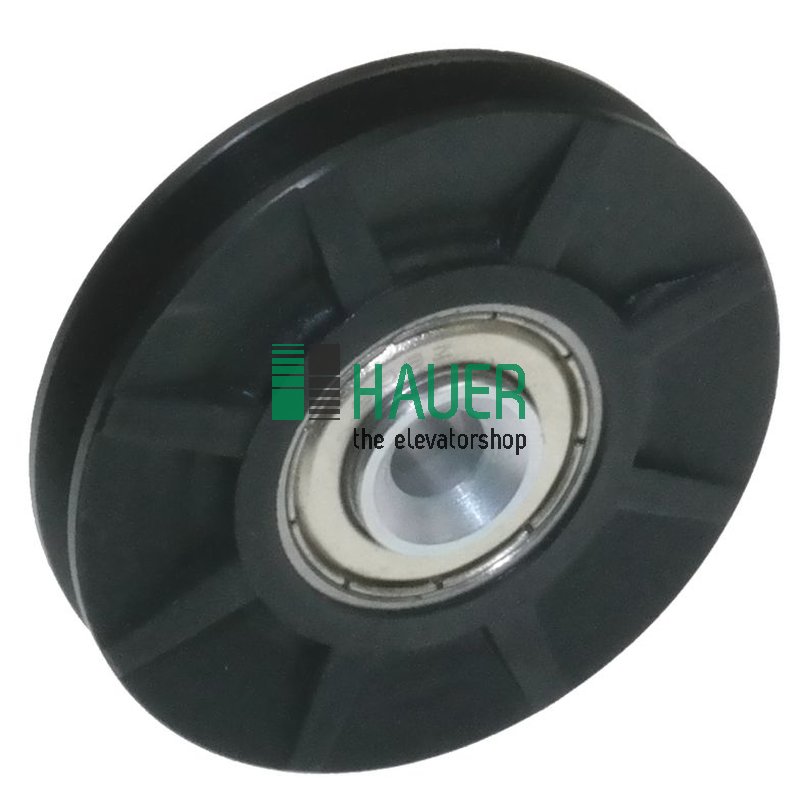

By 1970, PFB had started to specialise in the manufacture of components for lifts. Very soon, rollers, switches and overspeed governors from Modena began finding their way onto lifts across the globe.

This wasn’t without reason, as the components manufactured in the city on the edge of the Po Valley were of the highest quality, prepared with precision and attention to detail. Anyone wishing to install a sliding guide, a tensioning device or rope pulleys in lifts today would be hard pushed not to choose PFB products. There is no doubt that PFB’s successes can also be linked to the local identity – lo spirito di Modena. Indeed, it was here, back in the twelfth century, that one of the oldest universities in the world was founded, educating scholars in both science and art. Modena has since developed into a modern industrial metropolis and has been exemplary in combining cutting-edge science, innovative technology, and artistic design ideas.

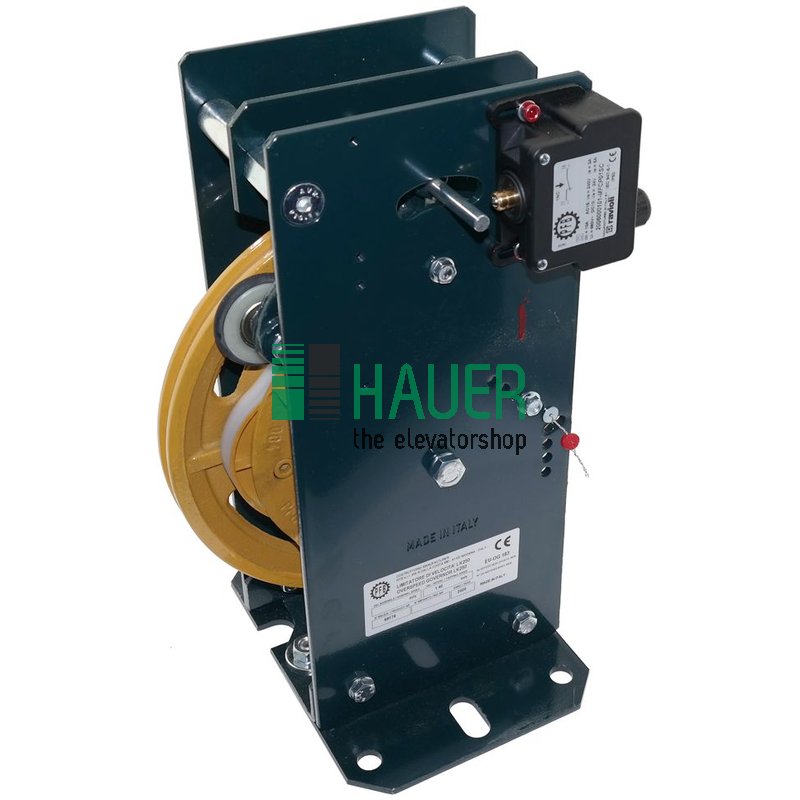

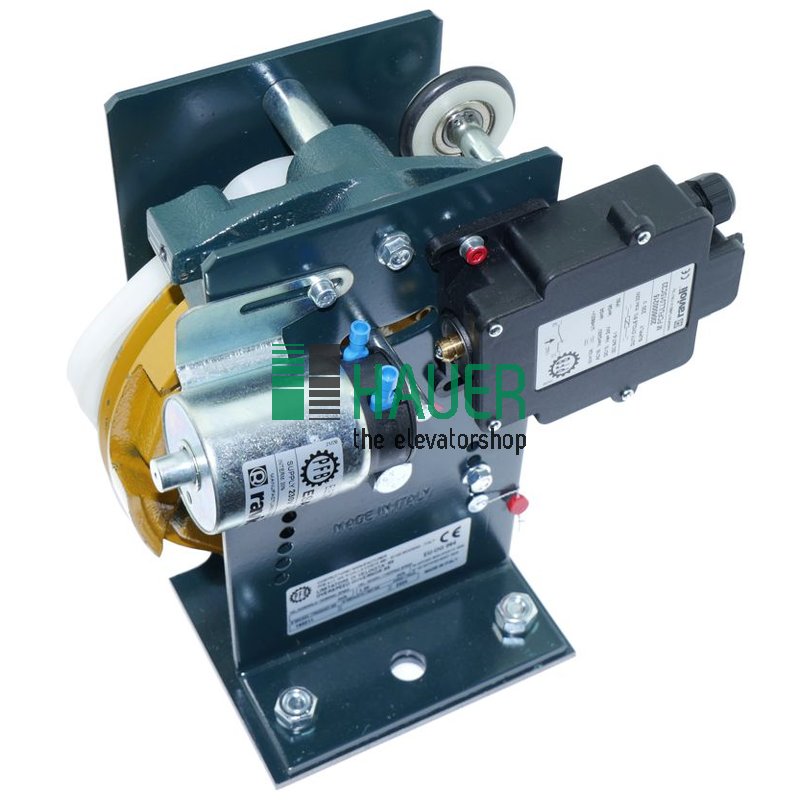

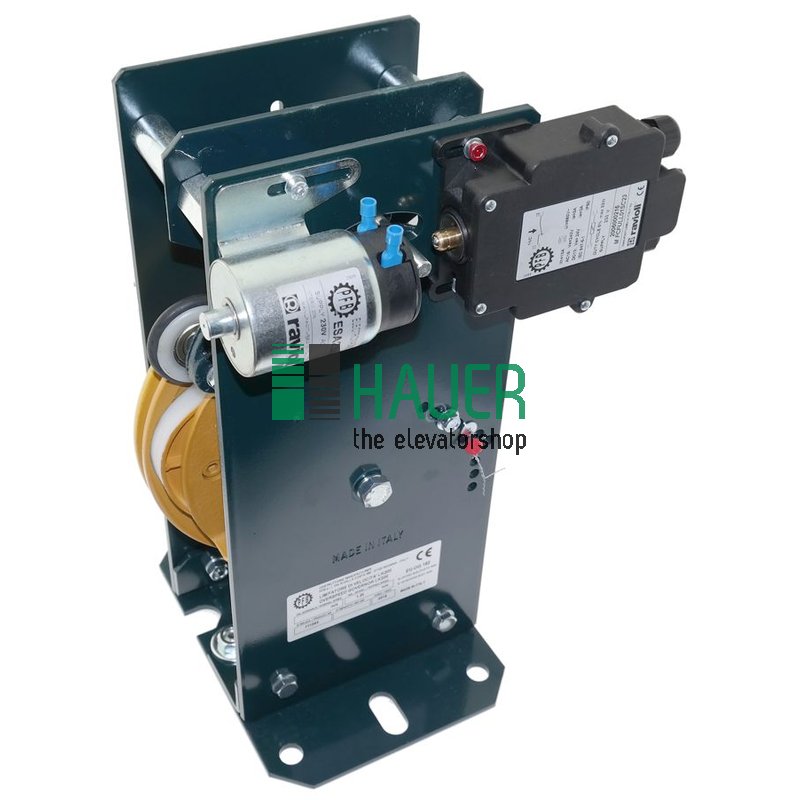

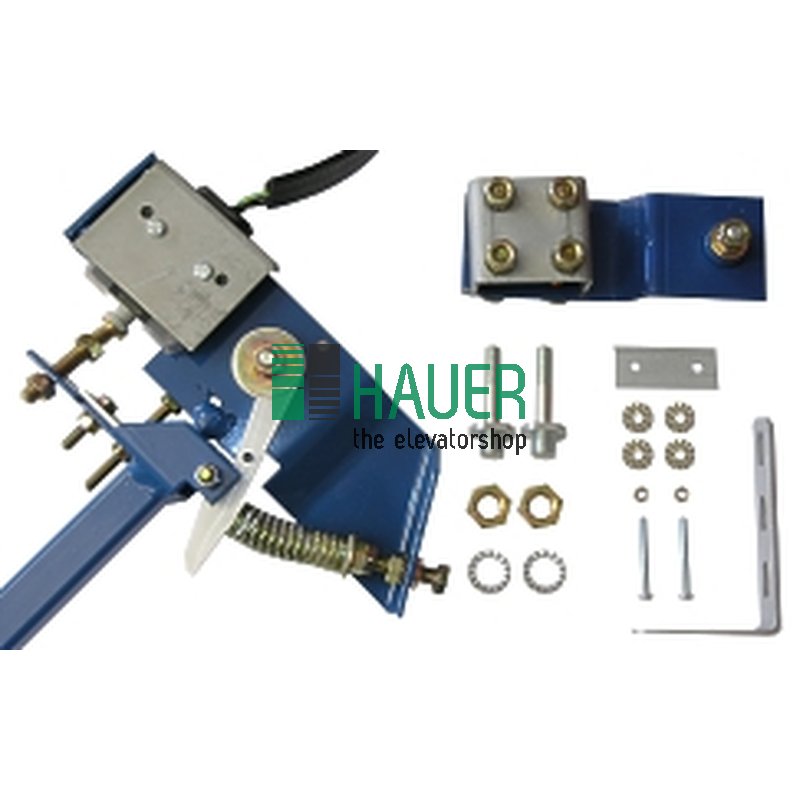

Setting standards – state-of-the-art overspeed governors

PFB made headlines within the lift industry, thanks to their unique product range, in 1983 – indeed, it was their overspeed governor that set new standards. These parts were further developed as a result and, in 1989, the company once again caused a sensation, this time with innovative safety gears for lifts, which also brought in new organisational and production goals. It’s no wonder, then, that PFB was part of the first international lift fair in Brussels in 1994.

Gaining approvals for pioneering products ushered in additional successes, further establishing PFB in the lift and escalator sector. Once more, it was primarily their variety of overspeed governors that ensured the company stayed in the limelight and continued to obtain international patents. Initially, PFB relied on ISO certifications. The company’s growth due to their increasingly high international profile led to the 1998 expansion of their historic plant and, in 2002, their manufacturing capacity was doubled with the addition of a second plant. The addition of ultra-modern new offices demonstrated their innovative potential even further.

When PFB received full TÜV approval for its range of internationally renowned safety components in 2015, it was clear that the Italian flagship company needed a partner in Germany that could fairly and economically distribute its essential spare parts and components, such as state-of-the-art safety catches, modern rope suspensions and innovative car counterweights.

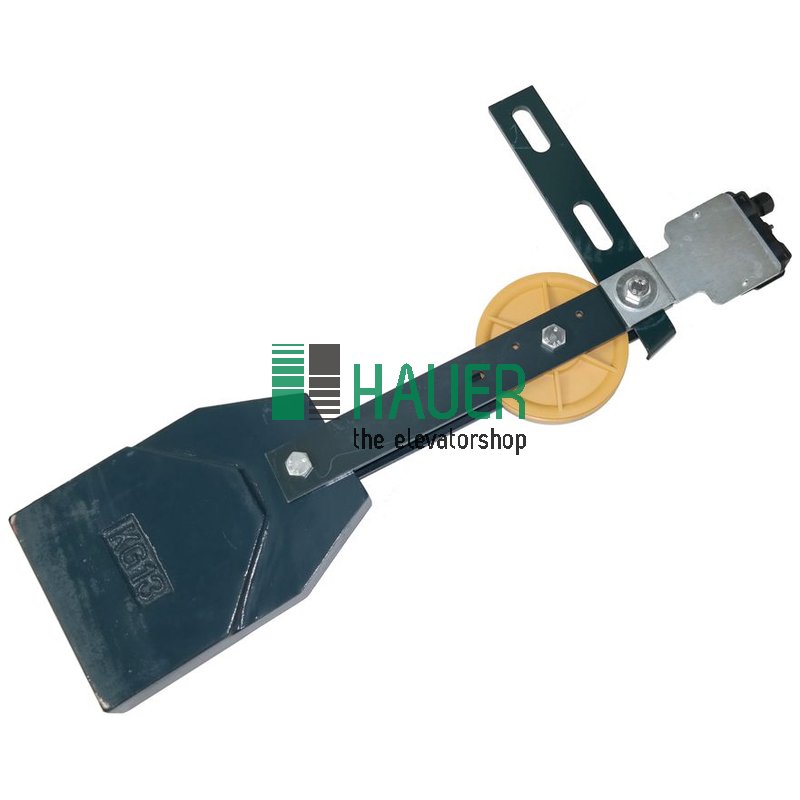

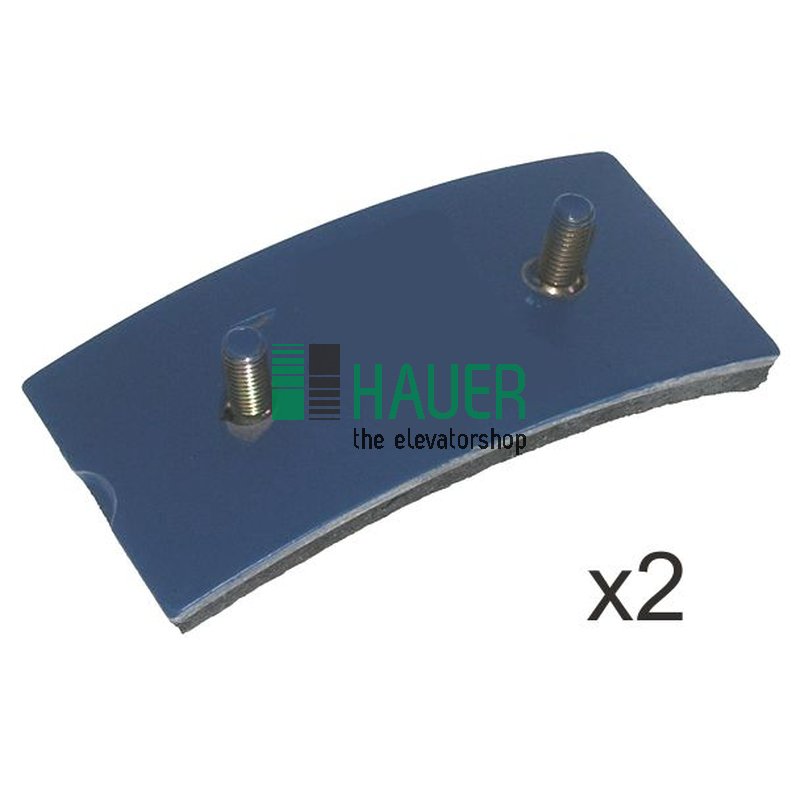

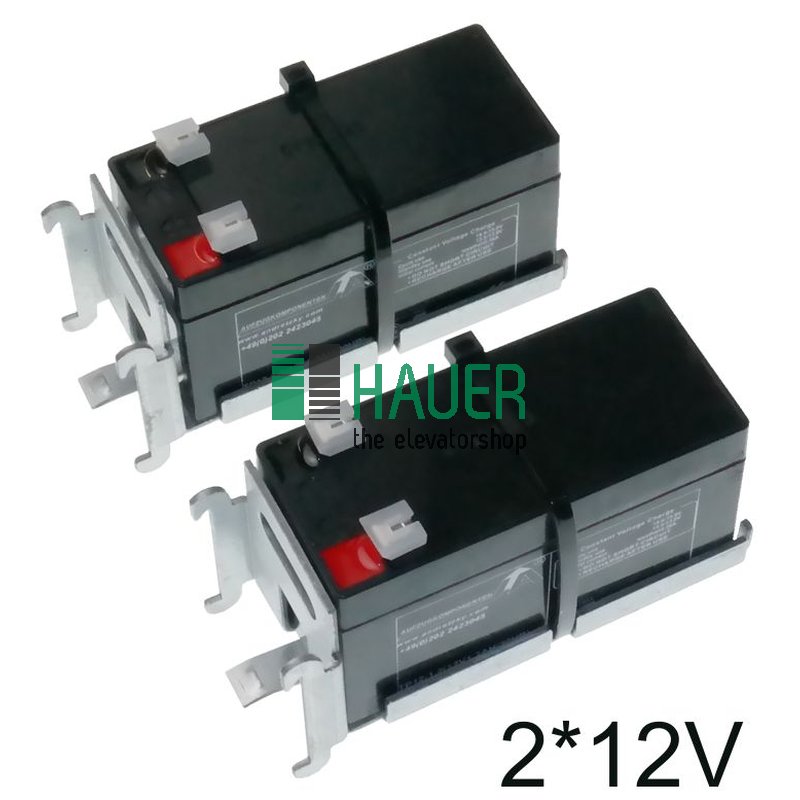

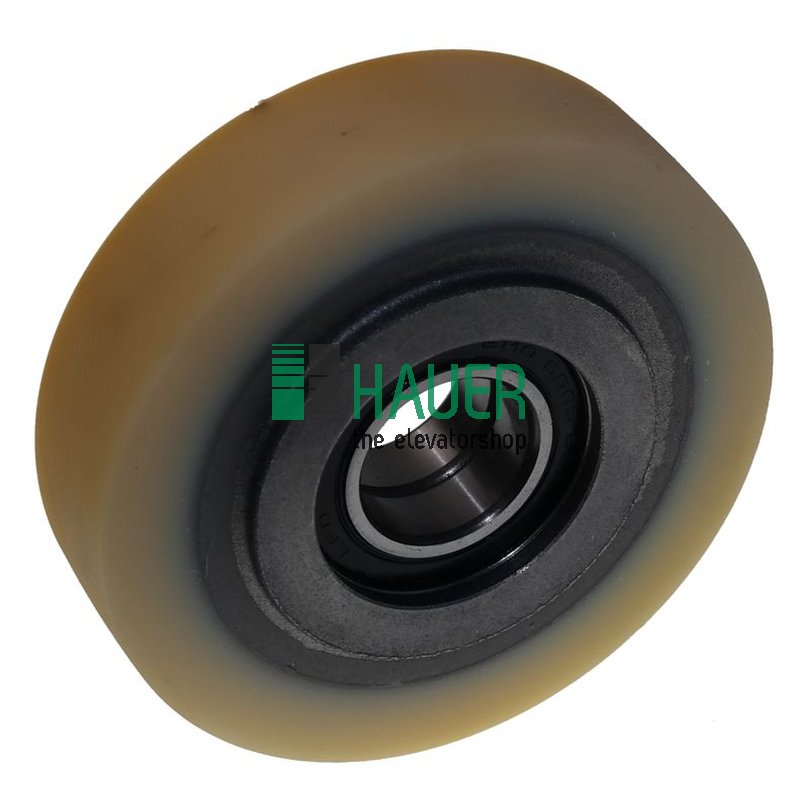

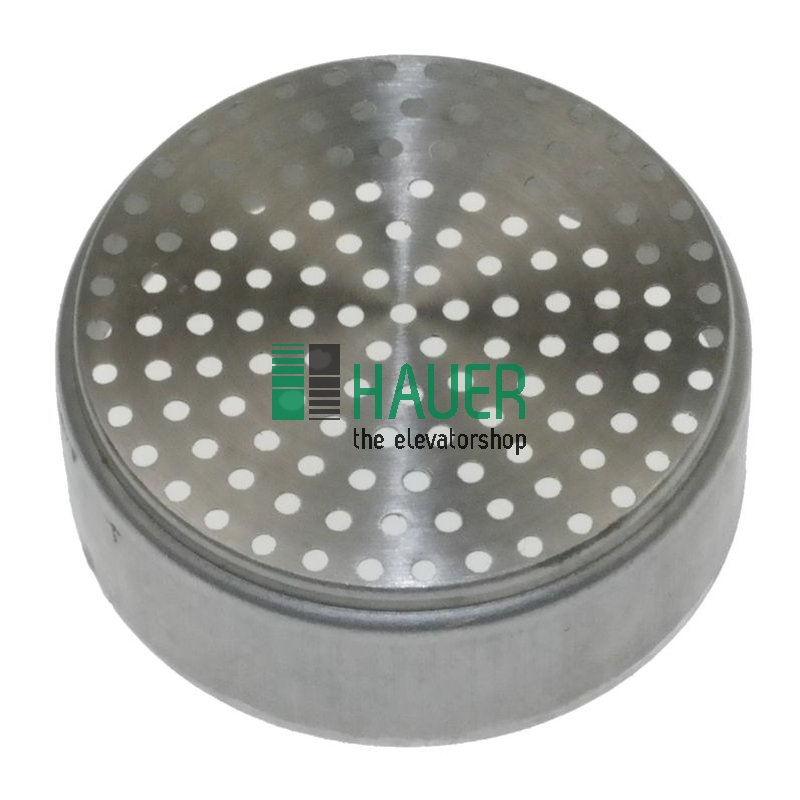

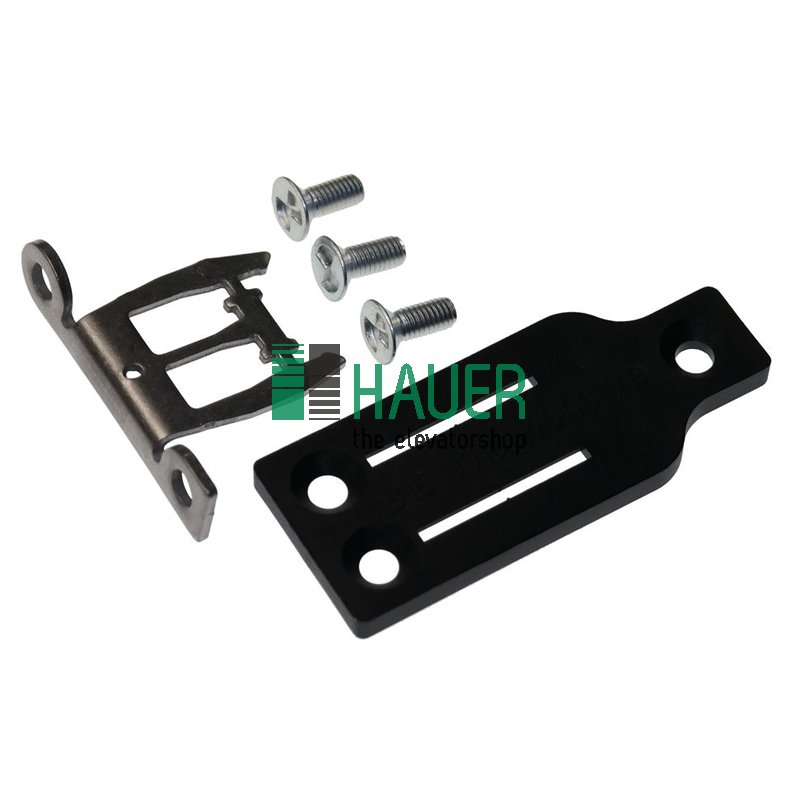

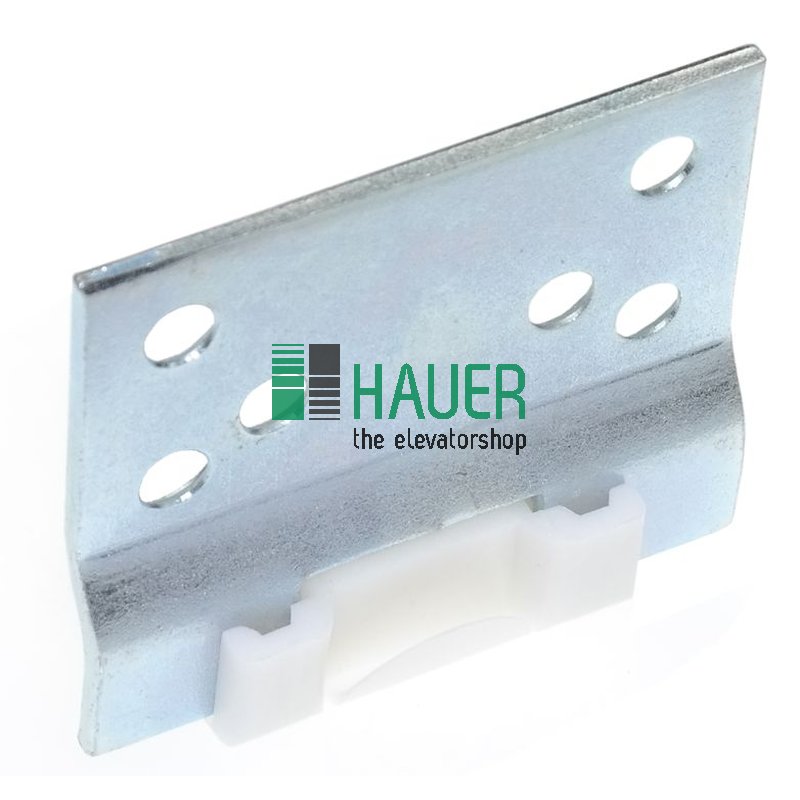

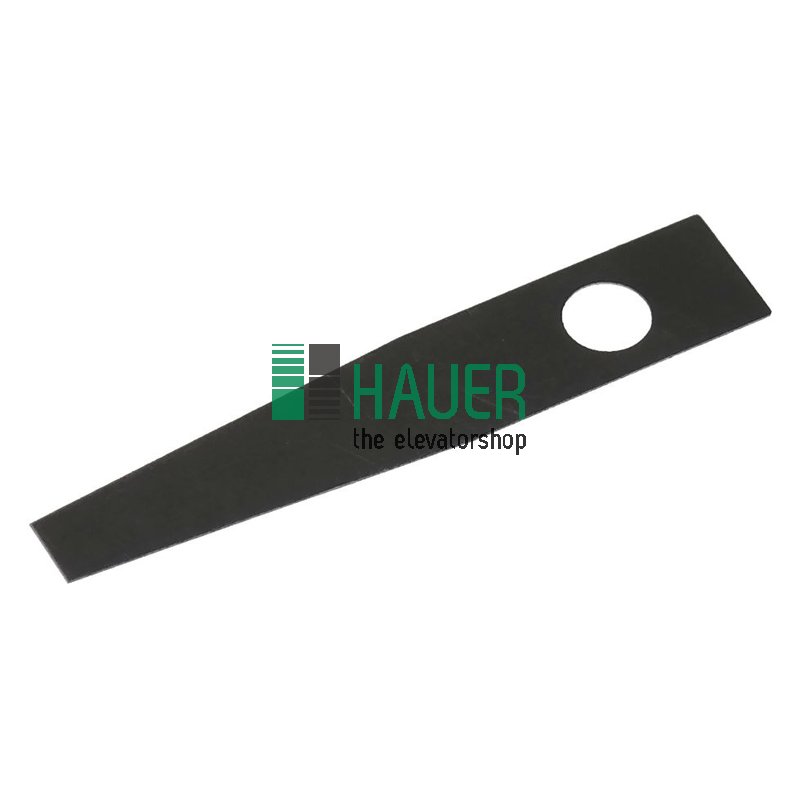

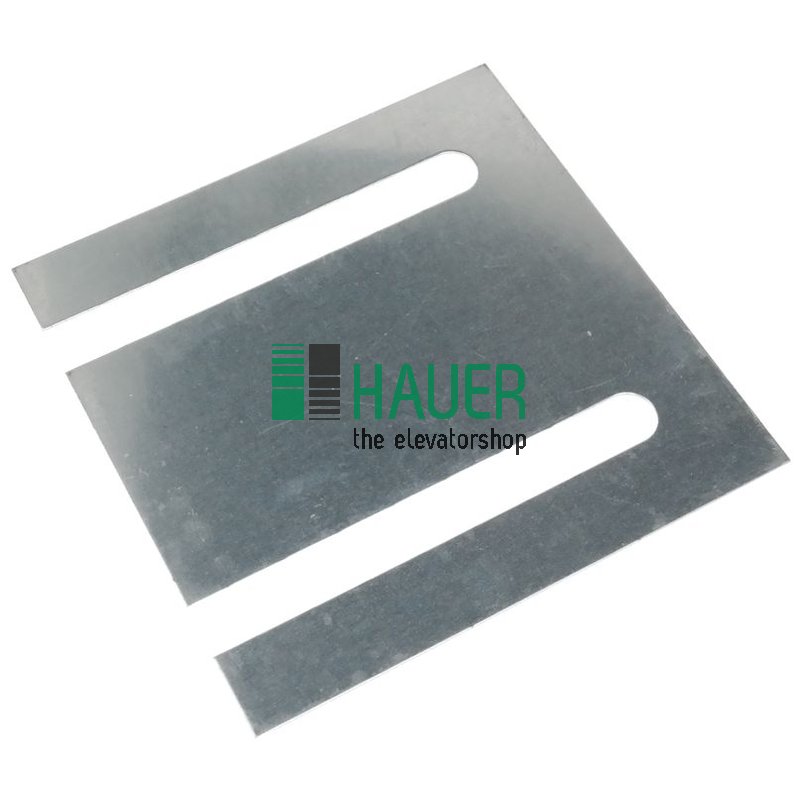

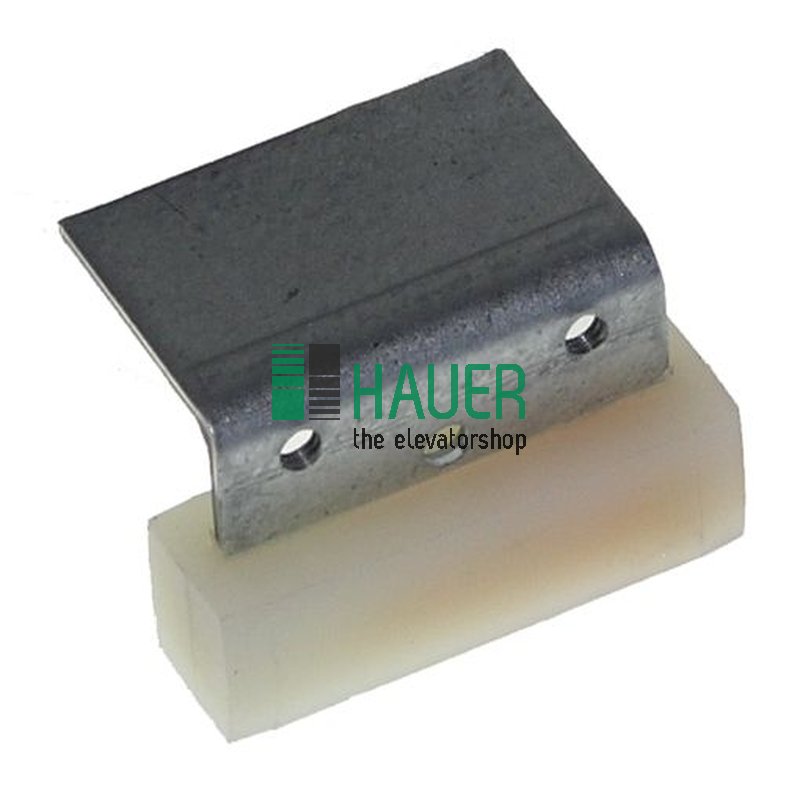

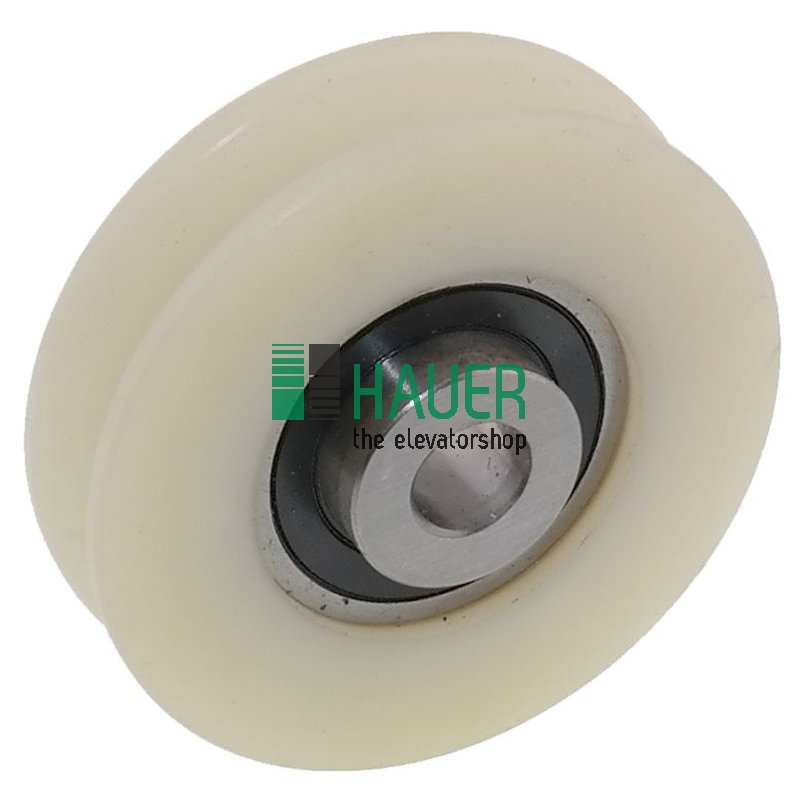

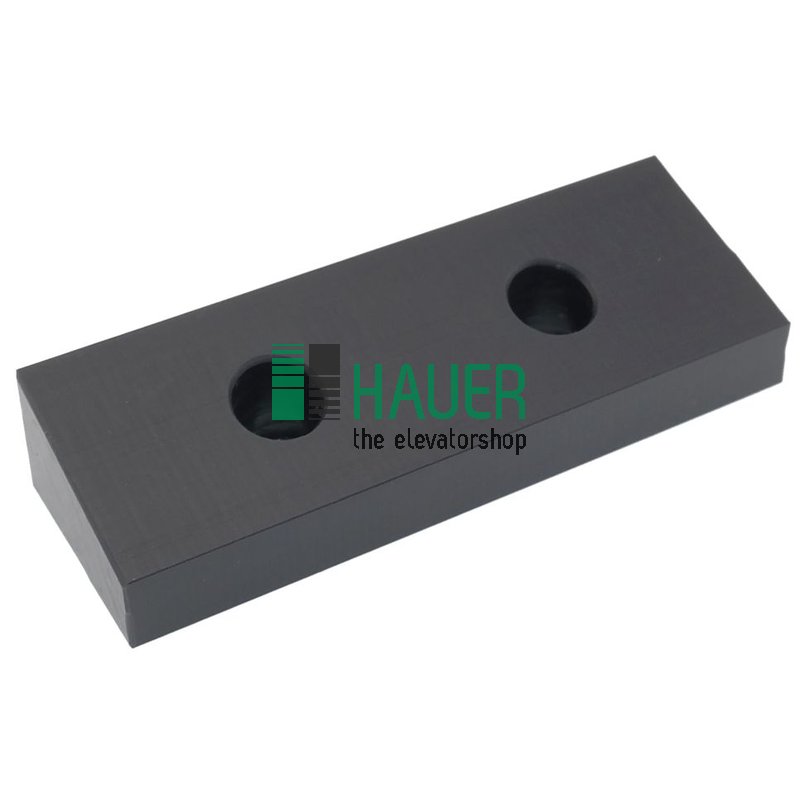

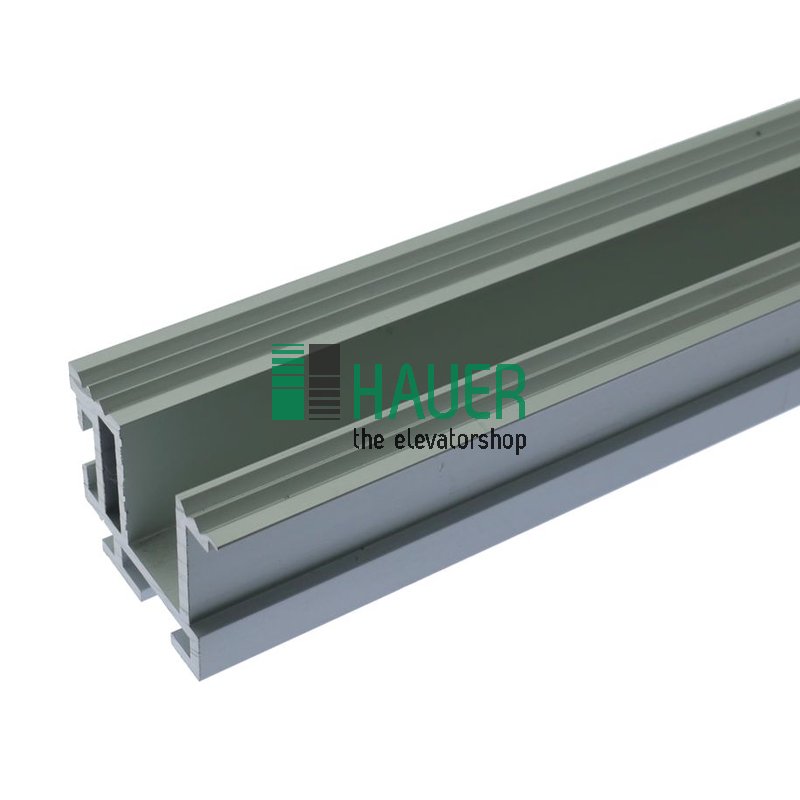

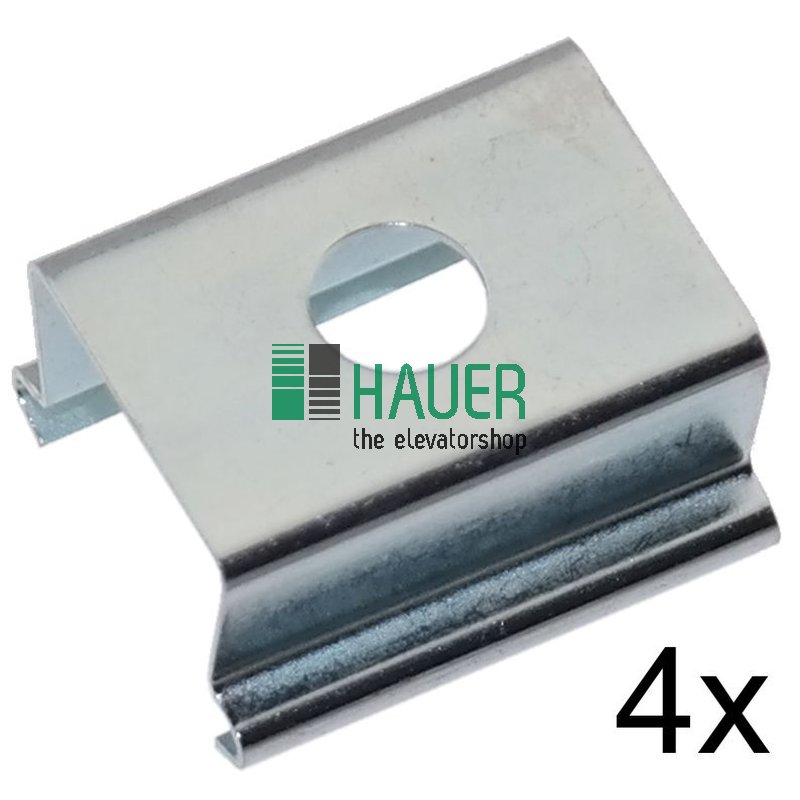

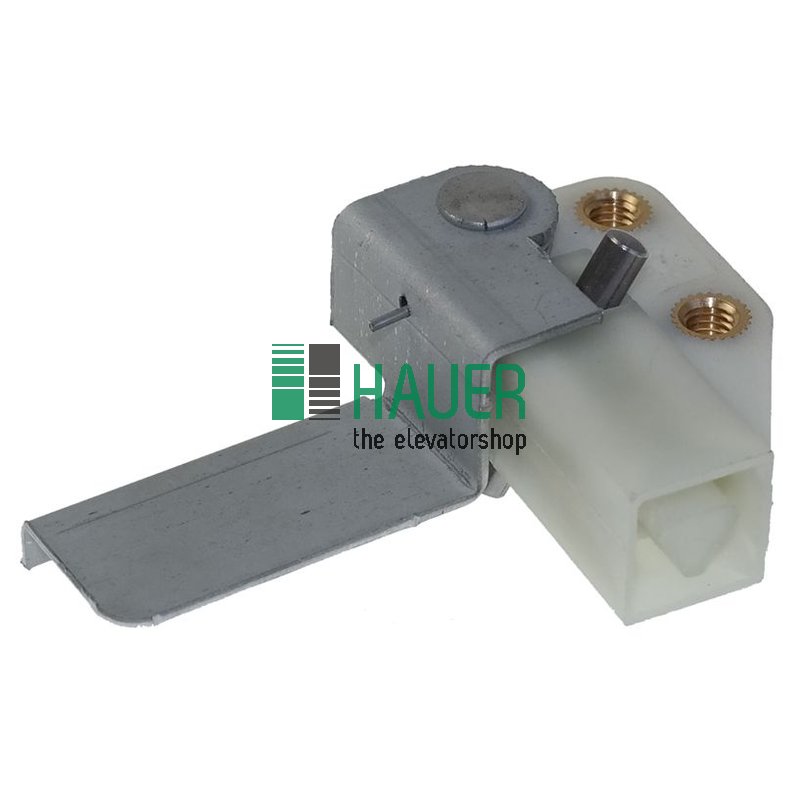

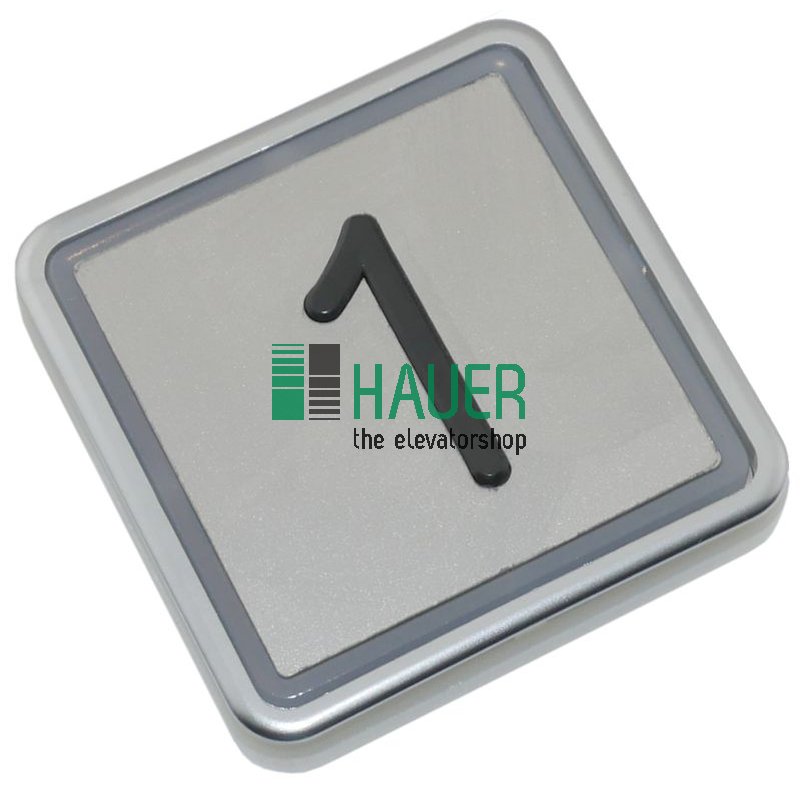

The PFB range at Hauer

Take a look at the Hauer product range today and, under “Brands” in the PFB section, you’ll find an impressive selection of high-quality spare parts and components – and the number on offer continues to rise. Whether you need a guide shoe with insert, a roller or switch for a folding door, a buffer, a tension weight, a roller for an overspeed governor or something else – PFB has you covered. They also manufacture guide shoes, tension weights, pulleys and rope anchorages for hydraulic lifts and rope-driven freight lifts.

One thing is clear – in several productive decades, the company has ensured that the “Made in Italy” seal is valued highly within the elevator industry. All components and spare parts are still manufactured on the PFB site in Italy. The company also ensures compliance with the highest quality standards in terms of the materials it uses. It even has its own testing tower in the old factory to test its own products.

Nothing stands in the way of the future. In 2017, management changed the corporate structure and began measures to digitalise the company.